Introduction to Encoder Sensing Technology

In the fast-paced world of technology, efficiency and precision are non-negotiable. Enter Encoder Sensing Technology—a game-changer that is reshaping how industries operate. From robotics to automation, this innovative approach has gained traction for its ability to enhance performance and reliability in numerous applications.

But what exactly is it? Why should you think about incorporating it into your business processes? Dive in as we explore the inner workings and advantages of Encoder Sensing Technology, revealing how it can elevate your projects to new heights.

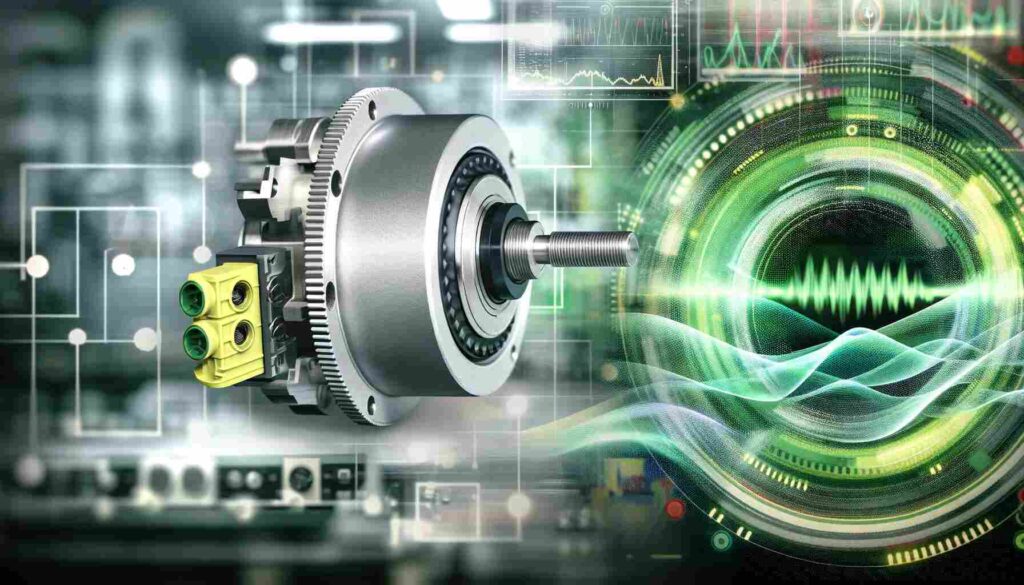

How does Encoder Sensing Technology work?

Encoder Sensing Technology uses precise measurements to convert physical motion into digital signals. At its core, it detects position, speed, and direction changes.

Encoders typically consist of a rotating disk or linear scale marked with distinct patterns. As the object moves, sensors detect these markings. This process generates electrical pulses corresponding to movement.

Optical encoders use light beams to read these marks, while magnetic encoders rely on magnetic fields for detection. Each pulse is translated into data that control systems can process.

This technology provides real-time feedback, allowing machines and devices to respond swiftly and accurately. Whether in robotics or industrial automation, encoder sensing enhances operational capabilities significantly.

Advantages of using Encoder Sensing Technology

Encoder Sensing Technology offers numerous advantages that enhance various industrial processes. One of its key benefits is increased accuracy and precision in measurement. This technology captures motion data with remarkable detail, resulting in reliable and consistent outputs.

Additionally, it significantly improves efficiency and productivity within operations. Systems can adjust quickly to changes by providing real-time feedback, minimizing downtime, and maximizing output.

Cost-effectiveness must be noticed, too. Reduced errors lead to lower waste levels and fewer resources consumed during production cycles.

Furthermore, this technology boasts many applications across different industries—from robotics to automotive manufacturing—making it versatile for many sectors eager for innovation. Each advantage contributes to creating smarter solutions tailored to evolving market needs.

Increased Accuracy and Precision

Encoder Sensing Technology dramatically enhances accuracy and precision in various applications. Encoders provide real-time feedback on position and speed by converting physical movement into an electrical signal.

This technology minimizes errors that can occur during data collection or processing. With high-resolution outputs, even minute changes are detected swiftly. As a result, systems can react instantly to any fluctuations.

In industries like robotics or automation, precise control is critical. Encoder sensing allows machines to operate within tight tolerances, ensuring consistent performance. This reliability reduces the risk of malfunction caused by miscalibration.

Furthermore, enhanced accuracy leads to better product quality in manufacturing processes. Equipment equipped with encoder sensors can achieve exact measurements repeatedly over time. This consistency boosts confidence and drives innovation across sectors looking for more dependable solutions.

Improved Efficiency and Productivity

Encoder sensing technology significantly enhances efficiency in various applications. Providing real-time feedback on the position and speed of moving parts ensures that systems operate optimally.

This precise data allows machines to adjust their actions swiftly. Consequently, production lines run smoother without unnecessary delays or errors. The immediate response reduces downtime, which is crucial for maintaining productivity levels.

Moreover, automated processes benefit immensely from encoder technology. It enables seamless integration with control systems, leading to quicker decision-making and less human intervention. This not only speeds up operations but also minimizes the risk of mistakes.

With enhanced efficiency comes an increase in output capacity as well. Organizations can achieve more within the same timeframe while maintaining quality standards—a win-win situation for manufacturers and consumers.

Cost-Effectiveness

One of the standout benefits of Encoder Sensing Technology is its cost-effectiveness. Companies can greatly reduce their operational expenses by implementing this technology.

Precision in measurements minimizes waste. When processes are more accurate, less material goes to waste, saving money over time.

Additionally, these encoders require minimal maintenance compared to traditional methods. This translates into lower labor costs and reduced downtime for repairs.

Moreover, the longevity of encoder systems means they don’t need frequent replacements. Investing upfront in a reliable encoder can yield significant savings down the road.

Businesses leveraging this technology often notice increased productivity, which directly impacts profitability. With all these factors combined, it’s clear why many industries are focusing on Encoder Sensing Technology as a smart financial choice.

Wide Range of Applications

Encoder sensing technology boasts a diverse array of applications across various industries. From robotics to automotive manufacturing, its versatility shines through.

In the industrial sector, encoders enhance automation processes. They provide real-time feedback on machinery positions and speeds, enabling precise control. This capability is crucial for maintaining optimal performance levels.

The aerospace industry also benefits significantly from encoder technology. Here, it helps in navigation and flight control systems. Accurate data ensures safety and reliability in critical operations.

Moreover, encoder sensing plays a vital role in consumer electronics as well. Devices such as game controllers utilize this technology for smooth user experiences.

Even medical equipment relies on encoders for accurate positioning during procedures or diagnostics. The health sector’s demand for precision makes this technology indispensable.

As industries continue to evolve, so will the applications of encoder sensing technology, driving innovation forward in exciting ways.

Future Developments in Encoder Sensing Technology

The future of encoder sensing technology is brimming with innovation. Advancements in materials and designs are on the horizon, making encoders even more robust and versatile.

Emerging trends point towards enhanced integration capabilities with IoT systems. This will allow for real-time data processing and remote monitoring, opening new avenues for automation.

Additionally, artificial intelligence is expected to be quite important. Machine learning algorithms can optimize performance by predicting failures before they occur.

Moreover, miniaturization techniques promise to create smaller encoders without compromising accuracy. These compact designs will enable their use in tighter spaces across various industries.

As demand grows for smarter manufacturing processes, encoder sensing technology will evolve rapidly. The next few years could see breakthroughs that redefine precision engineering altogether.

Conclusion

Encoder Sensing Technology represents a significant advancement in various fields. Its ability to enhance measurement accuracy and operational efficiency has reshaped industries.

As technology continues to evolve, the potential for encoder sensing is limitless. Emerging applications are being discovered regularly, which promise further improvements in automation and precision.

The growth of this technology also highlights the importance of investing in innovative solutions. Companies that adapt will likely lead their sectors while reaping substantial benefits.

Embracing these advancements fosters a culture of continuous improvement. It encourages businesses to rethink processes and explore new possibilities for enhancing productivity and quality.

Staying informed about developments in Encoder Sensing Technology can open doors to untapped opportunities across multiple domains.

FAQ

What is Encoder Sensing Technology?

Encoder sensing technology refers to a method of converting motion or position into an electrical signal. It utilizes sensors that detect changes in movement, allowing for precise measurement and feedback in various applications.

Where are encoders commonly used?

Encoders find their place in many industries, including robotics, manufacturing, automotive systems, and aerospace. They play crucial roles in motors, conveyor belts, CNC machines, and more.

How does encoder sensing improve accuracy?

By providing real-time data on position and speed, encoder sensing allows for tighter control over machinery. This leads to increased accuracy during operations like assembly or material handling.

Are there different types of encoders?

Yes! There are two primary types: incremental and absolute encoders. Incremental encoders measure the change in position from a set point, while absolute encoders provide a unique value for every possible position.

What should I consider when choosing an encoder?

When selecting an encoder for your application, consider factors such as resolution requirements, operating environment (temperature/humidity), communication protocols needed (like serial or parallel), and budget constraints.

Can encoder technology evolve further?

Absolutely! Advances are being made to enhance reliability and integrate with IoT technologies. Future developments may include wireless capabilities and improved data processing features that make them even more effective across multiple industries.